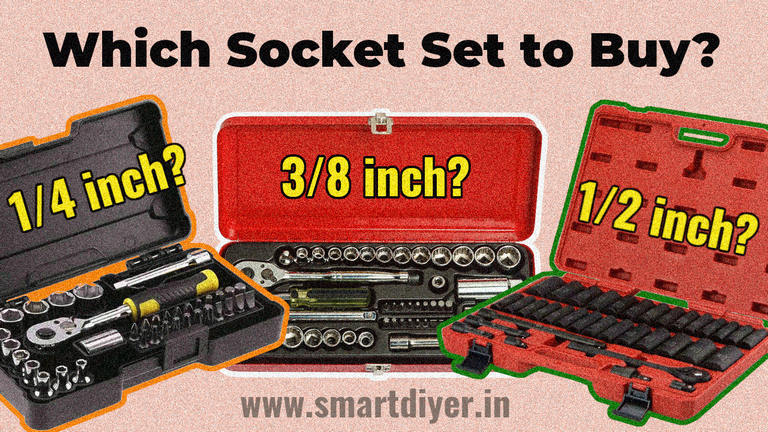

So, which Socket Set to buy? Should I Buy 1/4 inch or 3/8″ or half inch type? is a common question if you are buying socket set for the first time. In this article we will understand the complete basics of socket sets, their variants and just after reading this article in the next 3-5 minutes, you will be able to make a decision for yourself.

English or Metric?

So first, lets start with the country you are living in. Which standardization your country follows? Is it inch or metric? inch is nothing but English type (Imperial) and metric is nothing but mm (millimeters). That will be the first basic factor to decide.

Size of Ratchet

Size of Ratchet is nothing but the size of Socket square hole which will hold the Ratchet. Generally there are 4 types, the basic and smallest one is Quarter inch (1/4″), next 3/8″, most commonly used and preferred half inch type (1/2″) and the job specific and expensive 1 inch size. Selection of the ‘Size of Socket Set’ depends on the purpose of use, which is explained below.

Note: Some 1/4″ Socket Sets do not arrive with a 1/4″ Ratchet. You get a 3/8″ Ratchet instead. They also ship a 1/4″ adapter which you can used on 3/8″ Ratchet and use it as 1/4″. This is actually a good thing. 1/4″ Ratchet is too small for basic work. It will break/ bend easily. So, better buy Socket Sets with at least 3/8″ Ratchet.

Purpose of Use

If you are just starting out with DIY Projects, basic repair works where you drive bolts and nuts up to 10-12mm (or up to 1/2″), you can go with 1/4″ set box. The Quarter inch set is sufficient for all types of Bicycle works and minor Motorcycle works. Quarter inch Sockets are the cheapest ones you can buy.

If you drive bolts up to 16-18mm (up to 3/4″), you need a Ratchet Size of at-least 3/8″ where you can apply more energy (Torque) compared to 1/4 inches. Here I would personally recommend anyone to either choose between 1/4″ or 1/2″ and avoid the 3/8″ because, if you ever need to buy an aftermarket socket or you just broke one, finding the right sized ones may be difficult. This again depends on your country’s preferences. Here in India, 3/8″ Sockets are rarely used.

If you own a car or a motorcycle, or even a Truck, most of the jobs are heavy duty ones and need more torque. Removing Lug Nuts, Axles need a stronger tool. So if you are someone who does Engine DIY work, you need to get at-least 1/2″ size. Here you can drive Nuts and Bolts up to 28-30mm in Size. Larger the handle length, applying force is easier. Roughly cost twice the price of Quarter inch Sockets, investing in them would be really worthy.

If you want to drive large bolts above 36mm-80mm in size, you should buy the 1 inch size Socket Set. Generally driving such large sized bolts will be out of DIY context. So will end this topic here.

6 Point or 12 Point?

This means whether you need a Hexagonal or Bi-Hexagonal type socket. By the way, this is very important. A Hexagonal Socket has 6 Faces, just like any Bolt/Nut. A Bi-Hexagonal Socket has 12 Faces. So, which one should you buy? 6 Sided Socket or 12 Sided Socket?

Here is the simple explanation. If you work in confined spaces, example, working on an engine when already mounted on the vehicle, where you don’t have enough area to move your arms while turning the handle, you should be preferring the 12 sided socket. This helps you to move the bolt while still utilizing less work area.

Now, here is the drawback. If the bolt head is not in proper shape, the 12 sided socket will not the able to create wedge between their mating faces resulting in slippage. This will damage the bolt head even further. In such cases, Hexagonal type Sockets must be used. Even if the bolt has lost its faces, the 6 sided Socket will somehow make a fit wedge action between the mating surfaces.

There are some Nuts and Bolts which have 12 faces (12 points), where only Sockets with Bi-Hexagonal design are used. I would personally recommend getting a 6 Sided one instead of 12 Sided Socket Sets for DIY jobs. That’s a personal preference though.

Impact or Not?

If you have already seen them online or with someone, you might have observed its color. Was it Chrome? or was it Blackish? If the color is Chrome, it is intended for general purpose use where these sockets are not supposed to be used on impact wrenches of any type and shouldn’t be hammered. Hammer force will shatter them.

Now, don’t get confused, Chrome colored sockets will take light to medium hammer impacts. But impact force generated on Air driven wrenches is too high for them to handle. And hence you need to buy Blackish ones for such jobs.

Blackish color is the result when the steel is tempered. Steel is heat treated to withstand all types of impact forces involved in any type of operation. This increases the cost of production too. So, if you use impact wrenches, go with the Tempered/ Impact rated Sockets or else, for general DIY works, Chrome type will be just fine.

Have you ever broke a Ring Spanner in life? If yes, you probably did hammer it.

Other Aspects

Generally, if you buy a 1/4 inch Set, you get more number of accessories than 1/2″ box. Other than Sockets from 4-14mm, those accessories include, Screwdriver bits of Pozidrive, Philips and Slotted ones. They also include Hex Keys (Allen keys) and Torx Keys. If you ever plan to buy these Screwdriver bits separately, it would cost you about 40% of the 1/4″ Socket Set price. When bought together, it would be a good deal.

Quality doesn’t come at lower price. Good Brands make Good Products. If you want a product that lasts lifetime, get a good one.

If you buy Sockets from your local market individually, i.e, you pay for each socket separately, it will cost you almost 50% more money if you would have bought it in a set. Moreover, you get a Carry Case too. Carry Case always keeps Sockets organized, no chance of missing. If someone borrows a socket, by the end of the day you realize it. Carry Case keeps things compact and portable.

As the size of Ratchets increase, their connecting element sizes also increase. This helps to get more torque while fastening. This means, it is easier to drive a 10mm Bolt on 1/2″ Socket than on 1/4″ one. Like said, as the size increases, the work area required also increases. If you own a 10mm T handle, used it on confined spaces, it is not the same experience to use 10mm T Handle on Sockets. Sockets take more area than individual tools. So, every tool has its job. Choose wisely.

Box Contents

Ratchet (1/4″, 3/8″, 1/2″)

Already explained above. Just to remind you, Some Socket Sets are shipped with 3/8″ Ratchet. They also provide an 1/4″ adapter. The AmazonBasics Mechanics Socket Set (Pack of 40) is such type of Socket Set.

Extension Rods

Extension rods increase the working length. Spring type Flexible rods are also available but only in the smaller 1/4″ segment.

T-Handle (Sliding T Handle)

When overloading on Sockets, it is better to use T handle instead of Ratchet. While overloading, Ratchet’s internal mechanism may get damaged. So, better to be on safer side.

Universal Joint Socket Coupler

This coupler helps you get more area to move your arms while fastening at confined spaces. If you are driving cabinet hinge screws, this attachment will be useful. Hope you got the overall idea on Socket Sets.

Aap hindi language me kyo nhi likha hai english me padna aur samajhane me bahut kathanai hoti hai aur kitane logo ko english nhi aati hai my mobile number and whatsapp 9334968288 aur koi bhi aap se upkaran kase kharide ye mujhe samajh me nhi aata hai ya mujhe karna nhi aata hai kripaya samajhane ki kosis kare ya koi aasan tarika bataye 9334968288

Comment karne keliye shukriya ji. Abhi maine mera business stop kar diya.

Mujhe hindi sirf baat karne keliye aati hai. Likhna mushkil hota hai. Mai karnataka se hoon aur yahan hindi kam chalti hai