Here is everything you need to know about all Air Compressor Fittings. A general purpose Air Compressor has 2 outlets. One, with a regulated output and the other at the Tank, most of the cases it is unregulated and the user has to manually install the pressure gauge. To know more about Air Compressors, please read the Beginners Guide to Air Compressors.

In order to connect the Hose Pipe to the Tank output, you need some connectors. They arrive in various sizes depending on which size pipe you connect to which sized output valve. Generally called as Couplers, quick release type.

First let us know the Sizes of Couplers. 3 types of Couplers are available. Thinnest 1/4″, Medium at 3/8″ and Industrial 1/2″. Generally speaking, Tool specifications decide the Size of Connector. They can be made of Brass, Aluminium and Stainless Steel. For DIY and most Home Shop jobs, Quarter inch (1/4″) is more than sufficient. For a Paint Shop, which uses multiple Sprayers and Compressor which is not near the work, 3/8″ or 1/2″ can be used.

The amount of Air Flow needed for the tool decides Coupler size. If you use HVLP Paint Sprayer with a thin connector, you don’t get enough volume of air. Also, it is dangerous to connect a small tool with a large Coupler directly. It will simply damage the tool. So, if the tool requirement is 40 SCFM, 1/4″ can be used. Up to 60 SCFM, 3/8″ can be used and for anything above 60 SCFM, 1/2″ Coupler can be used.

Coupler Terminology

Important Information:

When it comes to the Male and Female fitting of the coupler, there are various designs depending on the brands. Some market it as Industrial and others as Automotive. Do not worry about it much. Because while purchasing, you will purchase it in a pair or from the same manufacturer or from the same local store. If the Plug doesn’t fit the Socket, it means the design is different. Instead of worrying about it just get a new pair. Moreover, while you purchase an Air Compressor, Threads are the only things you get on the Output Valves, Air Tools, Filters, Oil Separators etc. Rest of it, you need to build up.

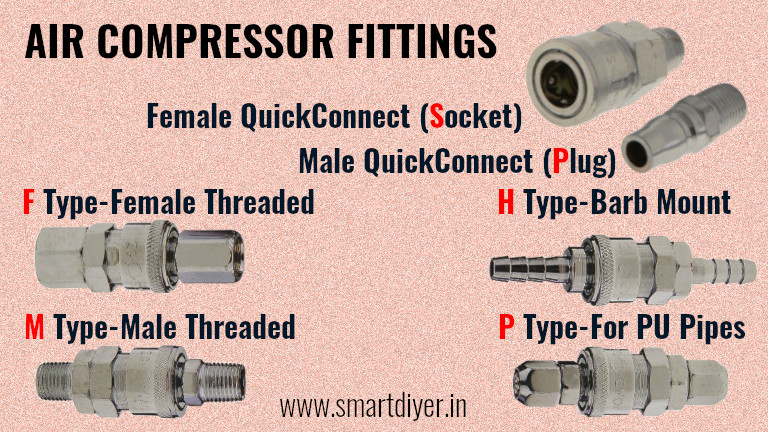

There are many types of ‘Connector Ends’ designed for all types of pipes. The Specs of Couplers is a combination of 2 Alphabets and 2 Numbers. It will be mentioned as SP20, PP20, SM30, PM40 etc, which will be discussed in detail below. Check the image on the top of this page.

The number 20 denotes Connectors relating to 1/4″ Coupler. 30 is for 3/8″ and number 40 is related to 1/2″ Coupler. Different Brands have different Terminologies. What matters is the Coupler Size and not Design of Socket or Plug.

The First Letter, if it is ‘S‘, it means the Coupler is Female part of the Quick Connector, called the “Socket”. Similarly, if it is ‘P‘, it is the Male part of the connector, called as “Plug”.

Typically, the Air Pipe coming from the Compressor should have Female fitting (Socket) and the Pipe coming from tool which receives the air has Male fittings (Plug). So remember, to connect any two type of connectors, the First Letters of both the fittings should be opposite.

The Second Letter can be H, F, M or P which will denote the type of Connection you want to have with the Pipe. Here it doesn’t matter what you use on both ends of the Connector. The deciding factor is always the first letter. Check the image on the top.

H type of connector is most commonly used. It is easy to connect. Insert the proper sized pipe in to the barb, using any Hose Clamp make it air tight. Simple. No special tools needed. Widely used among DIYers.

F Type coupler means it has Female threads inside.

M Type coupler means it has Male threads outside.

If you don’t like to use Hose Clamps, you can buy these M or F type connectors. Now, none of the pipes have threaded ends. So you need to install Threaded connector (Barb to NPT) on the Pipe first before you use these. To keep it air tight Teflon Tape can be used. So again, what type of Thread size you get depends on the Size of the Coupler.

If you buy fixed length Hose Pipes from your Local Store or Online Market, they already have Threaded Ends Crimped on them probably along with a Coupler Set, Male and Female at either ends.

Threads used on all Quick Connect Couplers are Tapered ones. Type of Taper thread depends on the country you live in, NPT or BSP. The reason here is to avoid Air Leakage. The more you tighten, the more it gets snug. Taper threads have always been used on pipes since 1900’s for all kinds of Fluids. Whenever you buy any Equipment that runs on Air Pressure, it probably has Threads somewhere. Make sure it is the Right type of Thread.

P type of fittings are widely used for ‘Pushfit’ type PU Pipes generally Blue/ Yellow in Color. For Steel Fittings shown above, PU Pipes of 8, 10 and 12mm can be used. There are even thinner PU Pipes for whom Plastic Type 1/8″ connectors are used. Such thin pipes are used in Automation Equipment and School/ College Projects to run Small Actuators.

Selection of Hose Pipes

You have to select pipes depending on their size which fits the Couplers. A 1/4″ Coupler has to be used with 1/4″ size pipe. 3/8th with a 3/8th pipe. You can however mix the connections but just to remind you, It is the Size of the Coupler which decides the CFM.

Hose Pipe Materials

There are n number of Materials from which Hose Pipes are made of. Here we will understand the most used ones for Small Shop and DIY works.

Rubber: The Premium material you can get for all purpose. The material is fully flexible. When circled and de-circled it won’t remember the curls, means, it will be fully straight again. Available in all sizes, 1/4, 3/8 and 1/2 inches.

PVC Flexible/ PVC Braided: Alternative to Rubber Hoses. Works as good as Rubber. Somewhat hard to circle and de-circle. Durable, available in all 3 sizes, not expensive.

Polyurethane (PU): Most commonly preferred type in small vehicle shops where they repair Motorcycles and Cars. These pipes arrive in thin sizes only. Probably you have seen them already, the Blue/ Yellow colored pipes which look like a spring hanging from the ceiling. They arrive in sizes of 6, 8, 10 and 12mm. Their specifications include their Inner Diameter and Outer Diameter. They arrive in 2 variants. First, similar to other pipes and Second, Spring type called as Recoil Hoses.

Thinner PU Pipes are used in Plastic Push-fit Connectors used to run small equipment like Bus Doors, Air Actuators, Air Switches and School Projects.

Hybrid Type: A combination of Rubber and PVC/PU.

Steel Pipes: Used in Industries and Shops to pass the Air Connections through/ on walls and above ceilings. Similarly as how we send LPG gases through pipelines. For all such connections Rust Free GI Pipes are used. It is always a good idea to Paint on them just to be future proof. Once Air reaches Room A to Room B you still need any of the pipes mentioned above to connect with the tools.

PVC Hard Pipes: Of Course! Not the thin ones used for making electrical connections. If used, they will just explode. They are not pressure rated. There are various categories of PVC Pipes. Some are rated @ some pressure to pass fluids like water and gas. You can always thread the pipe ends and apply enough amount of PVC Cement to air seal it. I would personally not recommend these type of connections and will prefer to choose metal over PVC. If these are any leaks after you make the connections, you cannot add bare cement. You may use Epoxy though. If it is metal having a small leakage, Brazing with some Solder seals it.

For Your Information (FYI)

Longer the Hose Pipe, lower will be the Pressure. If you have set the Compressor output to 90PSI and use a Hose which is quite longer than 10 feet, you will not receive 90 PSI at the Tool end. When Filters and Oil Separators are used, there will always be drop in Pressure. Connectors, Elbows, Bends, T Joints, ON/OFF Valves also decrease the Pressure.

Assume that if you needed 90 PSI at the tool, You need to Increase the Pressure output of the Compressor with the Pressure gauge connected at the tool end. So, you can get the correct number you need. Other way around is you can use Larger Fittings with Larger Pipes. If your Compressor supports only 1/4″ Fitting, you can still buy factory made 3/8″ Hose with 1/4″ fittings.

If your Tool needs 10 CFM, 1/4″ Connection is the one you need. At the same time 1/4″ QC Plug will be connected to the Tool. There are some adapters which mount to the 1/4″ Threads and are specified as “High Flow Fittings”. This means they will send more Liters of Air than specified. Use them only if needed.

Air Compressor Adapters & Accessories

Like said in the beginning, when you buy an Air Compressor, it has threads on the output. Threads can be either Male or Female depending on the brand. Even the Tool has Threaded input. You connect everything later using Hoses and make the system work. Below are pictures of such Adapters and Accessories which you can use to make your System work. Just by looking at the pictures you can make out what job they do. And this sums up the whole article.

Hard to find this information, thanks! It’s a nightmare to buy it online when there are several ones, euopean, asian, french, americans, and maybe more…