Here is an ultimate guide to Drill Bits. This article explains all types of drill bits along with its area of application. If you are a metalworker, woodworker or civil worker, I have covered you all.

METALWORKING DRILL BITS

HSS Bits

(Refer Image at the Top)

These are the cheapest bits that you can ever buy. In India, they will cost about 300 ₹ for one box of 10 bits (1.5-6.5 mm). If you are just starting out, invest in these.

Since they are made of High Speed Steel, they can drill through Mild Steel and Non-ferrous metals like Aluminum, Brass etc. They may dill slow, but justify the price. There is no protective coating on them. Hence spray a layer of WD40, store them and they will last forever without rusting. These bits are best suited for Handheld Drilling Machines.

Warning: Cheap HSS Drill Bits cannot drill Stainless Steel.

If you are looking to drill through Stainless Steel which is soft, you can buy premium quality HSS Bits which are graded as M2. If Steel is too hard, they only option is to buy M35, which is more discussed below.

Note: All the Drill Bits lose their capacity to drill overtime. This means they must be resharpened. If you feel that it acts like a blunt knife, get it sharpened. Be careful over the angle.

Providing cooling for Drill Bits increases its life. All metal drill bits can drill through Wood, Plastic, PVC & Fibreglass. More on Wood Drill Bits later.

All Drill Bits have specific RPM limits. A 10mm Drill Bit should not be operated more than 1000 RPM. For 5mm limit is 2000 RPM. For RPM Details, refer the manufacturer charts.

Titanium Coated Bits (TiN and TiCN)

These bits are basically the same HSS bits we discussed above. They just look different due to the Titanium Nitride Coating on them. They are not actually made of Titanium as they are advertised.

The TiN Coating increases their ability to preserve sharpness from heat generated in the drilling process. So, it is preferred to drill softer metals like Aluminium & Brass. When less heat is produced, drill bits can protect their cutting edges from blunting too quickly. And this is the reason some manufacturers claim their TiN coated bits have 6X more life than normal HSS bits. Once the TiN coating wears off, it can be used as a normal HSS bit itself.

Coming to the cost, cheaper ones are priced at 1.5 times the cost of HSS Bits. Very good quality TiN Coated bits can drill through Stainless Steel only to an extent till the coating erases off. Not all the TiN coated drill bits are the same. They all vary in quality according to the brand. If a manufacturer claims that their Titanium Drill Bit can be used on Stainless Steel, then chances are that the coating is Titanium Carbon Nitride (TiCN).

The best quality Titanium Drill Bits are similarly priced to Black Oxide ones or even more. This varies from Brand to Brand though.

HSS Black Oxide Bits

These bits are stronger than plain HSS bits. Even though the material is HSS, don’t judge that they work the same as the above ones. Branded manufacturers produce better qualities.

The Black Oxide Coating provides them a protective layer increasing its life. These bits can drill Harder Steels except Stainless. In order to drill Stainless Steel you must go with a Cobalt Drill bit.

Coming to the cost, they are priced at twice the cost of HSS Bits. These are very best suited for Handheld Drilling Machines. They don’t break that easily as HSS ones. They can drill faster than the basic ones.

Cobalt Drill Bits (HSCo)

Now again, as the name indicates they are not 100% made of Cobalt. There cannot exist a 100% Cobalt Drill Bit. These Drill Bits are made by adding a very small Percentage of Cobalt to the HSS Drill Bit composition. This cobalt composition increases the hardness of the drill. And that percentage is mentioned on the bit itself. It will be either M35 or M42.

M35 has 5% Cobalt and M42 has 8% Cobalt. Having more is not always better. An experienced machinist can help you with this.

You should be more careful while drilling with Cobalt Bits on handheld Drilling Machines as they are very brittle. A small wobble will just shatter it.

Coming to the cost, they are priced at nearly 3-4 times the cost of HSS Bits. And again, it depends on the manufacturer.

Tip: If there is a bit which can slice through Stainless Steel like butter, it would be the Carbide Insert Drill Bit. Lathes and Milling Machines use them.

Hole Saws

There are two options for drilling larger holes. One is to get a big expensive drill bit and the other way is to get a Hole Saw. The advantage is more in a Hole Saw than a larger bit. Because a drill bit takes more time to drill and the removed material will not be in one piece. Moreover Hole Saws are preferred to cut pipes for a circular edge and to cut notch.

Similar to Haxo Blades, there are two types. One is made of teeth hardened mild steel and the other from HSS which is also called as Bi-Metal Hole Saw.

The Bi-Metal can cut through Wood, Aluminium, PVC and Mild Steel. Lubrication is much necessary during operation to extend its life.

Step Drill Bits

If there is a bit that can be called ‘One Man Army’, this is it. Step Drills. Every bit has its own drill range. They can be used on any corded, cordless and bench drills and can drill on almost any surface. Whether it can drill Stainless Steel or not, it depends on the material type I explained earlier.

Since they have thicker body, they are strong and won’t break that easily. Shank is the weakest part though. One limitation is that they just can’t dig deep. Since they are short, they are best suited for sheet metal work.

The problem with normal twist drills is the burr. Generally you need to remove the burr after drilling. If step drills are used, there is no necessity to use another counter sink bit again. The same step drill can remove the burrs too.

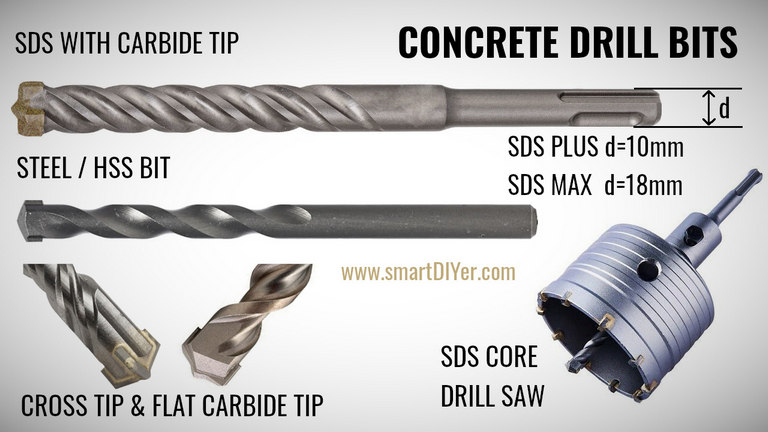

CONCRETE DRILL BITS

Steel Drill Bits

These are the cheapest drill bits that can drill concrete. In the professional world they are not that preferred. The reason is they have round shanks. These bits can be used on drilling machines without SDS Chucks.

That means you can use this drill bit on any machine that supports round shank bits. Whether you can drill or not, depends on the machine itself. It should create Hammer Force for these drills to work.

Not all Drill Bits have round shanks. They can be Hexagonal too. Whether they have a round or hex shank, Jacobs Chuck supports both.

Most manufacturers produce round shank bits from 2mm to 10 mm only. Producing more than 10 mm bits doesn’t make much sense as bigger drilling machines won’t support them.

If you are DIYer and don’t drill concrete very often, then this will best suit you. Just make sure that the Drilling Machine you are going to buy should have an Impact/Hammer function in it.

Note: If you are thinking of using SDS Shank Bits on cheaper machines, trust me, they don’t work. Even if they fit, they wobble. Because a cheaper drill chuck has 3 jaws. When they contract, they won’t find a solid surface to hold on.

SDS Drill Bits

If you want to drill larger holes above 10mm, you must be buying a SDS Hammer Drill. SDS Drill Bits support only SDS Chucks.

There are two types of SDS Bits, SDS Plus (most commonly used) and SDS Max ( for Heavy drilling)

SDS vs SDS Plus vs SDS Max

I have not included the plain SDS bits. They are extinct now. Their newer generation is SDS+. If you already own or found some SDS Bits, you can use them on any newer SDS+ Chucks. Vice-versa is not possible. If you have an old SDS Drill, you can’t use it with SDS+ Bits.

SDS Plus has a Shank Diameter of 10mm. SDS Max has 18mm Shank. It is obvious that thicker shanks are for larger sized drills and large Chipping Hammers.

SDS Plus widely used in Hammer Drills. SDS Max is used in Demolition Hammers. I have not included SDS Chisels in this article.

Note: Almost all the SDS Bits have Carbide Tips. Carbide is much harder than Stainless Steel. So if you encounter Rebars while drilling through Concrete, the Carbide Tip will take care of that.

Flat Tip vs Cross Tip SDS Bit

Generally SDS Plus bits arrive in two types. One with Flat Tip and other with Cross Tip. There is not much difference what you use, but I would suggest you with Cross Tip. The prices are more or less the same.

I dimensionally compared a 16mm Cross Tip SDS+ Bit, Flat Tip has diameter of 16.29mm and Cross Tip has 16.07mm diameter. This would likely mean that the Cross Tip is there to smoothen out the hole and assist pass through rebar.

SDS Drill Bits don’t arrive in diameter less than 5mm. Not all diameters are produced. They usually have 5, 6, 6.5, 8, 10, 12, 13, 14, 16, 18, 20, 22, 24 and 25mm Diameter as standard. They arrive in various lengths depending on how deep you need the hole. SDS drills also have the other deciding factor, the Length. As far as I know, lengths up to 1 meter are available.

Core Drilling Saws

These types of Saws are used to drill Holes in Concrete. Widely used for Plumbing works. For more professional use, Core Drilling Machines are itself available. If you are a DIYer, you may buy these SDS Saws as cheaper alternative. Here you can’t supply water cooling for the saw like the professional ones. But, providing regular cooling intervals can increase its life. Real Core Drilling Machines are very expensive.

WOODWORKING DRILL BITS

Wood Drill Bits

Wood drilling bits are extremely sharp and always have a spur pointed end known to be Brad Point. They are available in sizes from 3mm to 10mm. Since these have flutes, it can extract the drilled material out like any other twist drill.

Auger Bits

These bits have a different flute design. Auger bits are used to drill larger diameter holes. These were the first type of drill bits used for woodworking. They were common among hand operated drills. The flutes have screw type design that can extract wood chips automatically. The drawback is that they are expensive. They are available in sizes from 6mm to 25mm. (¼” to 1”)

Spade Bits

Also known as Flat Bits. These bits are cheaper alternatives to Auger Bits. There are no flutes here. This means extraction will be manual. Spade bits have a shank diameter of about 8mm and can support any machine. They are available in sizes of 10, 12, 16, 18, 20 and 25mm.

Forstner Drill Bits

Forstner bit works similar to the Spade Bit and provides a clean surface finish around the circumference and a flat bottom. They are preferred when the cut is either overlapped or at the edge (to cut a semicircle).

Hole Saws

Wood Hole Saws are designed similar to Metal Hole Saws. The difference here is the material used is High Carbon Steel. They are available in sizes from 25mm to 64mm.

Circle Cutter Drill Bit (Adjustable Hole Saw) can also be used to drill large holes. This can drill holes from 30mm to 120mm.

Note:

For Drilling Glass and Tiles/ Marble diamond drill bits are used. For smaller holes, Spear Head bits are used and for larger holes, Hole Saws are used.

Spear Head bits range from 4mm to 12mm. Hole Saws range from 10mm to 80mm.

Tip: How to differentiate Drill bits for Wood, Concrete and Metal?

Metal Drill Bits have a Blunt end. Wood Bits have Spur Point. Masonry Bits have Wings at the tip.

Great tutorial. Thanks

Thank You