In recent times there emerged a Diamond Cutter Disc which can cut metal. Previously they were used only on Tiles/ Masonry work. If you are a metalworker, I recommend you to own one for its extraordinary benefits which I am going to discuss in the table below.

| Abrasive Cutting Disc | Diamond Cutting Disc |

|---|---|

| Pricing: Very Cheap. Single 4″ Disc costs 15-18₹ in India. | Pricing is premium quite higher than Diamond Disc for Masonry work. A 4 inch Diamond disc for metal can cost a minimum of 500₹ |

| Cutting Speed: Abrasive discs are the fastest to cut among all types of cutting wheels. | Slower in cutting speed. No worries, but still accomplish the job. About twice slower than Abrasive |

| Safety: Unsafe. Can shatter if Angle Grinder is not held properly. Never use this disc without Safety Guard. | Very safe. Purely steel disc except the diamond coating at the top. Will not shatter. Using Safety guard is still recommend. |

| Life: You already know! Abrasive disc consumes fast. | A single Diamond disc is equivalent to about 80 abrasive discs. Not according to me! according to manufacturers. Who tests that? |

| While in usage this disc gets shorter and shorter. If you are cutting a pipe of 1 inch diameter, a new abrasive 4 inch disc can cut up to 2 such cuts in one pass. After that, disc gets shorter. It can be still used but definitely cannot be used to cut in one pass. | This disc never gets shorter. This is the No.1 Benefit. If you use an Angle Grinder Stand Accessory, this is the must use disc. No hassle of changing discs again and again. Mount it, Forget it! |

| Cannot be used sideways. In the sense, de-burring with the same disc is a risky process. Technically, this disc shouldn’t be used for grinding. | This is the No.2 Benefit. This disc can be used for light grinding purpose. Not for professional grinding though. Can be used for light de-burring tasks after cutting. This disc can withstand angular loads. |

| Creates a lot of mess. Sparks are heavy. Abrasive powder is spilled all over the working area. | This is the No.3 Benefit. Likely to be very clean. No abrasive dust. Less sparks. |

| Can be used continuously until the person handling the machine gets tired. | Cannot be used continuously. The disc needs at least 10 seconds of rest every 30 seconds. Not a deal breaker though. Provides temporary rest for the user too. |

| Surface finish on the parts is very neat. Very less grinding is required. | Very rough surface finish is obtained. Needs finishing if not used for welding. |

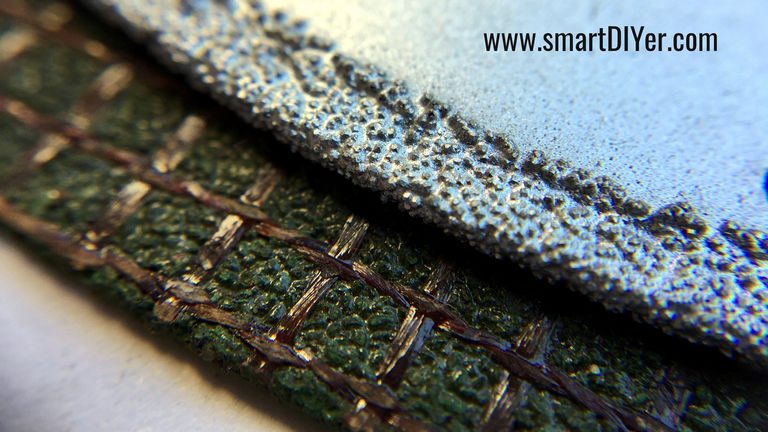

In the below picture, the disc on the left is used and to the right is Brand new. Macro view of the disc structure. Holes on the surface of the disc are provided for cooling just like the holes in motorcycle disc brake.